The World’s Highest Volume Metal 3D Printing Company

A California based Metal 3D Printing Company is transforming the production of precision stainless steel components with immediate turnarounds, and no up-front costs.

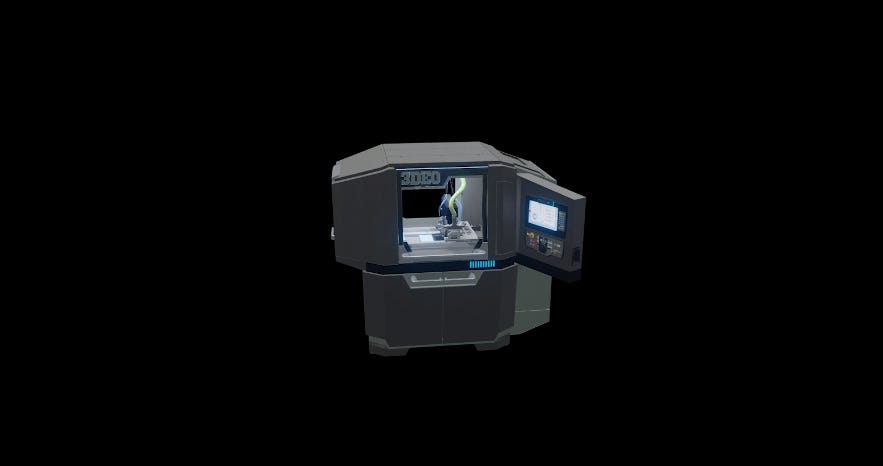

What is 3DEO?

Established in the year 2016, 3DEO is an innovative low-cost metal 3D printing technology company. Metal additive manufacturing technology of 3DEO is used for the manufacturing of high-quality parts with a substantial low cost of manufacturing, complex or traditionally impossible designs, immediate turnaround times. 3DEO is the manufacturer of complex stainless-steel parts for its customers with a vast range of applications from a wide range of industries. The expertise of the company in complex geometries design for additive manufacturing (DFAM) and small (< 4 cubic inches) components are some aspects that makes 3DEO stand out from its competitors in the market. The company operates with 12 employees in its facility expanded over 13, 000 sq ft in Torrance, CA. The competitive stance of 3DEO lies in its 3D metal parts which offer higher volumes at lower costs than other metal 3D printing technology.

At 3DEO, the needs of surgical device partners are considered to be very important and products are designed to make these partners face complex challenges in their high precision metal components. Starting from prototyping to verification and validation and to finally the manufacturing process, every step requires close consideration, real-time innovation, documentation compliance as well as the right partner to optimize the entire process from conception to completion. This is the primary reason as to why more and more surgical device companies are using 3DEO and its technology instead of metal injection molding and machining.

3DEO Manufacturing Cloud

The manufacturing Cloud of 3DEO integrates innovation across the entire production system–printing, augmented reality, robotics, advanced data systems along with a platform that manages all aspects from designing to the final product. This tightly integrated system is connected through a software which is devised to collect real-time image data from programs, machines and robotics, managing of AI integrations and creating a closed loop feedback to enable automation at scale.

Jarvis OS is the proprietary software of 3DEO. The software inputs customer digitized models and makes use of in-house computational geometry for converting into digital work instructions. The machine learning module provides feedback for monitoring and controlling end-to-end platform.

3DEO Founders

The founders of 3DEO are:

Matt Sand, Co-Founder & President

Matthew Petros, Co-Founder & CEO

Products and Services

3DEO is the manufacturer of low-cost, high volume metal 3D printed parts along with supplying to a wide range of industries including industrial, automotive, dental, medical, firearms or aerospace. The manufacturing capabilities of 3DEO are well-suited for a number of applications in need of 17-4 PH stainless steel, complex components including:

Robotics

Guides

Connectors

Jaws

Connectors

Valves and pumps

Clevises

Bone Scrapers

Fasteners

And others…

3D Printing Of 3DEO

The proprietary and patented metal 3D printing technology of 3DEO is Intelligent Layering. This is the only metal 3D printing technology which defeats the conventional way of manufacturing in terms of quality, cost and turnaround. Through the patented technology of 3DEO, companies can compete over price and quality with shorter lead times, no up-front costs and unlimited design freedom. The 3D printing technology of 3DEO includes:

Material properties exceed MPIF Standard 35, the MIM Standard

No tooling required and no need to buy expensive molds

Material properties exceed MPIF Standard 35, the MIM Standard

Intelligent Layering was designed specifically to deal with cost and low throughput problems that are typically a part of metal additive manufacturing. The final result is an ultra-low-cost machine which also virtually eliminates the amortization of machines as an integral part of cost driver. In addition to this, Intelligent Layering involves no degrading process which means that part-to-part and machine-to-machine repeatability enables a high yield process. Because of these features. 3DEO offers the best surface amongst all metal additive manufacturing in the as-sintered state.

Quality of 3DEO 3D printing technology

A big problem in the 3D printing industry today is that it fails to hold itself to similar standards like that of traditional manufacturers. A part ordered to a traditional manufacturer expects that all parts are similar. For 3DEO, quality of 3D printing refers to the fact that whether it’s the 10th part or the 10,000th part, they are all the same. All parts are dimensionally same along with similar finish of the surface and ultimately, similar functionality. Behind quality procedures, there is a traceable manufacturing process which is data-driven. It is associated with a closed-loop feedback control from machines and sensors that track real-time information. In additional to this, material specifications are also very important. 3DEO has in-house characterization capabilities for testing and measuring environmental, mechanical, chemical as well as metallurgical properties o the manufactured parts. 3DEO is also accredited 3rd party testing labs along with academic research labs. For 3DEO, Predictability of performance is of crucial importance for scaling operations. Consistent monitoring is undertaken so as to assure that manufacturing is under control and that the quality remains consistent over time.

Why metal 3D printing

In the aspect of additive manufacturing (AM), 3D printing adds in many benefits and possibilities. Unlike conventional manufacturing methods like CNC machining or metal injection molding (MIM), 3D metal printing gives manufacturing flexibility, designing freedom as well as an extraordinary speed to market. There are very few geometric limitations and the updating of designs is also an effortless task as there is no tooling, molds or lengthy setup times. Moreover, 3D printing is also able to allow companies compete over cost basis in comparison to traditional manufacturing with the right types of parts.

Robotics

Since its inception, 3DEO is built over automated technology. A prime example of this includes software and hardware inclusive of automatic build ejection, robotic instructional operations through geometry and computer vision modules, automated pick and place, along with a printer control that helps Jarvis in updating status in real-time. The robots of 3DEO automated production process reduce cost aspect and assure high quality and speed. Automation and robotization is crucial for mass production 3D printing and we have wrote about it in this article.